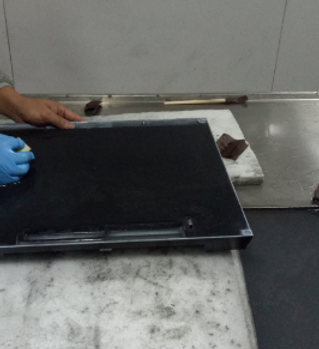

Prototype Smooth

Smooth, is a surface modification technology.Generally refers to the use of rough objects (with high hardness particles, etc.) to change the surface physical properties of materials through friction a processing method, the main purpose is to obtain a specific surface roughness.It's the most widely used in prototyping.

Sand Blasting

Sandblasting can cause the prototype's external surface or shape to change, because of the impact of abrasive on the surface and cutting function. So that the surface of the workpiece to obtain a certain degree of cleanliness and different roughness, and the surface of the part to improve the mechanical properties.To improve the product fatigue resistance, increased the adhesion between it and the coating, extended the durability of the film , but also conducive to the flow of paint and decorative.

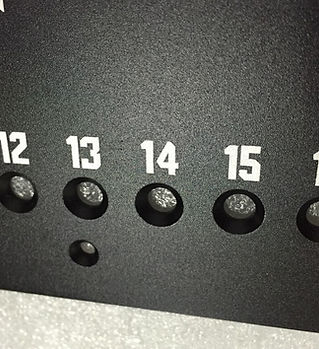

Laser Etching

Laser etching is a surface treatment process, which some similar to screen printing.It is etch the image with AI file on the prototype surface(about 0.8mm deep).Plastic and metal material can be applied.

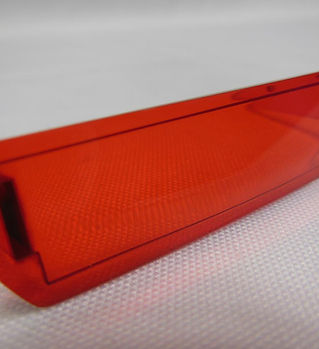

Plastic Dyeing

PC and PMMA prototypes are often use dyeing treatment.Such as car headlight, medical facility,it's a good way to get the color effect for clients prototyping project.And water cup is extensively used to test the design.

Prototype Polishing

Polishing refers to the use of mechanical, chemical or electrochemical role of the workpiece surface roughness to reduce, in order to obtain bright, smooth surface of the processing methods. Is the use of polishing tools and abrasive particles or other polishing medium on the workpiece surface modification. ABS,PMMA,aluminum,brass etc are workable for rapid prototype.

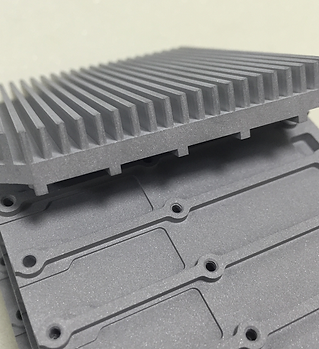

Prototype Anodizing

Anodizing is an electrochemical technique for changing some details of surface properties. Anodize aluminum, magnesium and titanium,etc are workable for us.

There are many reasons with an anodized surface treatment. It improves corrosion protection, surface hardness, wear resistance, aesthetic appearance and the adhesion of paints and primers. It also reduces electrical conductivity, helps to dissipate heat and reduces surface reflection.

Electroplating

Electroplating is the process of plating a thin layer of other metals or alloys on some metal surfaces by using the principle of electrolysis.It is an electrolytic action to make metal or other material prototypes with a metal film to attach a layer of technology.To prevent metal oxidation (such as rust), improve wear resistance, conductivity, reflective nature. Corrosion resistance (copper sulfate, etc.) and enhance the aesthetic role are its benefits.

Prototype Painting

Painting is available for rapid prototype and small batch in SG Prototype.Any desired surface finish, including high gloss, matte, semi-gloss, metallic flakes and customized textures are able to produce by our technicians. We also do color-matched tinting for clear plastic parts.

Silk-Screen

silk-screen is a great way to make customers product unique in the world for their company logo,or other special image design necessary for their prototypes.

Water Transfer Printing

Water transfer printing is some like silk-screen(limited with prototype shape) method.But it allows patterns and designs to be applied to any shaped objects,which can be hold a base coat and safely submerged in water that dipped.This technology are getting more and more fascinating in manufacturing filed.

Get In Touch Today

The customer service team responds online 24 hours a day, providing full-cycle services from demand communication, progress feedback to after-sales support to ensure worry-free cooperation for customers.