Best 5 Rapid Prototyping Solutions for High-Quality Results

- helen84827

- Sep 2, 2025

- 1 min read

Updated: Sep 17, 2025

In today’s competitive product development cycle, rapid prototyping plays a crucial role in turning ideas into reality. By creating a prototype before mass production, companies can test functionality, validate design, and optimize performance. Here are five proven rapid prototyping solutions for achieving excellent results:

CNC Machining

CNC machining provides high precision and durability. It is ideal for functional prototypes that require strength, accuracy, and tight tolerances.

3D Printing

3D printing ( SLA/SLS/ FDM) delivers smooth surfaces and fine details, making it perfect for appearance models and early-stage design validation.

RIM ( Reaction Injection Molding)

Ideal for small batches and large-sized parts. Performance close to mass-produced parts: by choosing different PU materials, it can simulate ABS, PP, PC, transparent parts, soft rubber parts, etc.

Vacuum Casting

Vacuum casting is suitable for small batch production. Using silicone molds, it creates multiple copies of a prototype at a lower cost compared to injection molding.

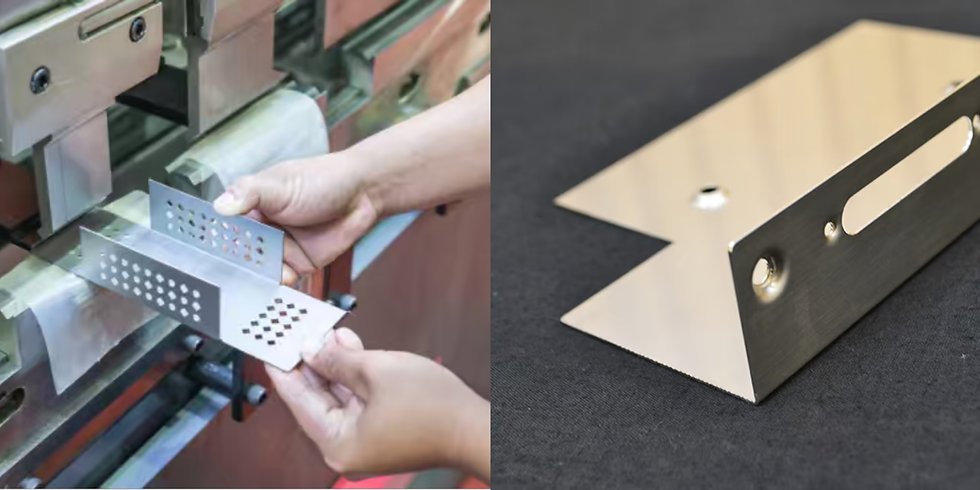

Sheet Metal Prototyping

For enclosures, brackets, or industrial parts, sheet metal prototyping ensures reliable strength and rapid turnaround.

Why Rapid Prototyping Solution Matters

By combining these five methods, companies can reduce time-to-market, minimize design risks, and achieve better product quality. Whether you are developing consumer electronics, medical devices, or automotive components, choosing the right rapid prototyping solution ensures efficiency and success.

Contact us for a custom solution for your next prototyping project.

Comments