Prototype Surface Finishing Of Electrophoresis

- Jul 29, 2025

- 2 min read

Surface treatment of electrophoresis (electrophoretic coating or electro-deposition) is a key process in the manufacturing of high-end prototypes, especially suitable for lightweight material parts such as aluminum alloys and magnesium alloys that pursue metallic texture, uniform coating, and strong corrosion resistance.

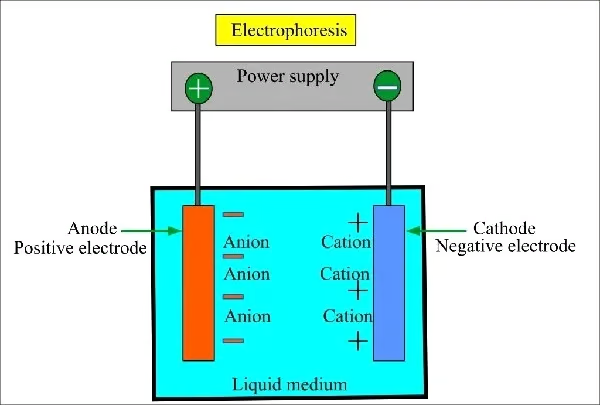

What is electrophoresis surface finishing?

Electrophoresis surface finishing forms dense coatings via electrolytic deposition: Charged aluminum workpieces are immersed in electrophoretic paint. Direct current drives paint ions to deposit uniformly, forming a nano-level coating with exceptional adhesion after thermal curing.

Advantages of the electrophoretic coating process

Coating Uniformity

Even complex geometric structures (such as deep holes and edges) can be fully covered without dead zones, avoiding the sagging issues common in traditional spraying.

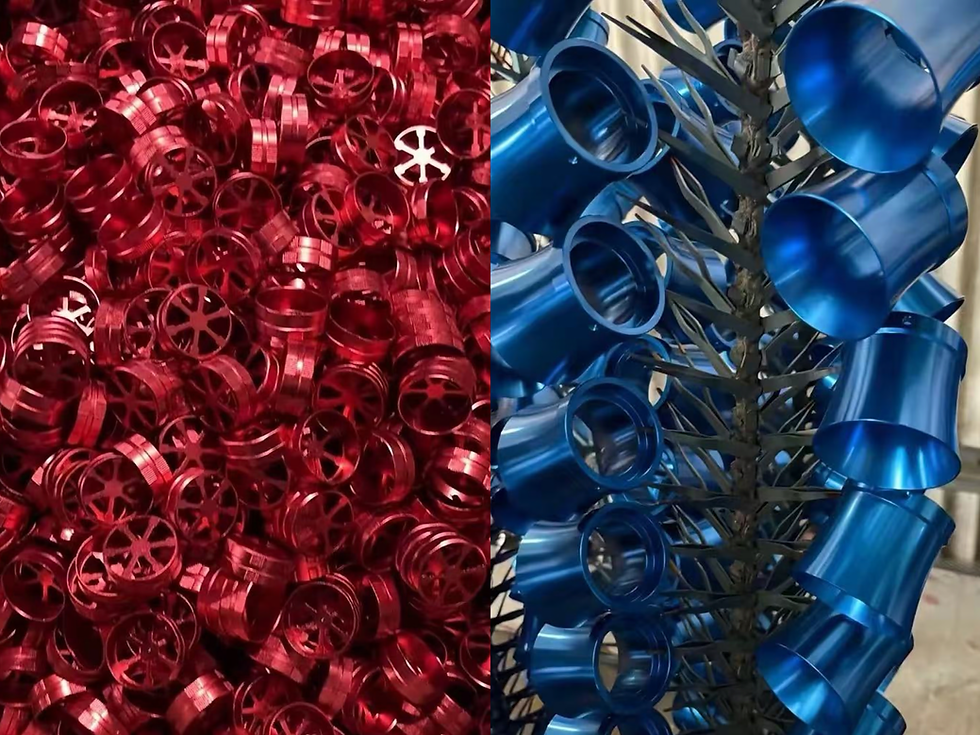

Colour Expression

Customizable high-end metallic tones such as shiny gold, silver, and champagne can be achieved, enhancing the visual quality of the product.

Environmental Protection and Energy Efficiency

Paint utilisation rates exceed 95%, far surpassing spraying, with extremely low solvent emissions.

Why is electrophoretic deposition on prototypes recommended?

1) Corrosion and wear resistance

The electrophoresis layer effectively isolates contact with chemical media, making it suitable for harsh environments such as marine equipment and automotive components.

2) Enhanced product value

Electronics industry: Combined with conductive oxidation processes, it can shield electromagnetic interference, making it suitable for communication equipment prototypes.

3) Consumer goods sector

Enhances design aesthetics with a metallic finish, such as smart home casings.

4) Cost Efficiency

Automated production lines are suitable for batch processing, with lower per-unit costs than anodizing.

No need for multiple grinding and polishing steps, reducing delivery lead times.

FAQ

Q1: How to address pinholes on the surface after the electrophoretic coating process?

A: Check if the pre-treatment degreasing is thorough. It is recommended to use an ultrasonic cleaning process followed by deionised water rinsing, and control the electrophoresis tank solution temperature at 28±2°C.

Q2: Is electrophoresis suitable for small-batch prototypes?

A: Yes! Through an intermittent electrophoresis tank solution, the minimum order quantity is 10 pieces, with a sample production cycle of 1-3 days, meeting the rapid validation needs during product iteration periods.

As a professional prototype manufacturer, we offer customised E-coating for prototype surface finishing to small-batch trial production, ensuring your product debuts in optimal condition on the global market.

Contact the technical team to obtain free Surface finishing techniques for prototypes.

Comments