Injection Molding Surface Finish: SPI standards

- Aug 5, 2025

- 2 min read

In injection molding, the surface finish of the mold will significantly affect the final appearance and function of the product. The SPI (Society of the Plastics Industry) is an independent trade organization based in the U.S. It has established some standard injection molding surface finishes.

What are SPI Surface Finish Standards?

The SPI surface finish standards define the polish levels for molds, directly impacting the visual and functional quality of plastic parts. These standards categorize finishes into four grades(A, B, C, D), each with three sub-grades. They range from high-gloss to matte and textured surfaces, catering to diverse application needs.

The following list shows all the polished surfaces specified by SPI

SPI Standards | Finish(Type) | Typical Surface Roughness Rs(µm) |

A-1 | Super Glossy | 0.012 to 0.025 |

A-2 | High Glossy | 0.025 to 0.05 |

A-3 | Normal Glossy | 0.05 to 0.10 |

B-1 | Fine Semi-Glossy | 0.05 to 0.10 |

B-2 | Medium Semi-Glossy | 0.10 to 0.15 |

B-3 | Normal Semi-Glossy | 0.28 to 0.32 |

C-1 | Fine Matte | 0.35 to 0.40 |

C-2 | Medium Matte | 0.45 to 0.55 |

C-3 | Normal Matte | 0.63 to 0.70 |

D-1 | Satin Textured | 0.80 to 1.00 |

D-2 | Dull Textured | 1.00 to 2.80 |

D-3 | Rough Textured | 3.20 to 18.0 |

1. Grade-A (High Gloss/Mirror Polish)

High Gloss is a Grade-A finish achieved through polishing, which creates glossy surfaces on injection-molded parts.

2. Grade-B (Semi-Gloss finish)

Semi-Gloss is a grade-B finish option made by grit sandpaper, and it creates a slightly rougher finish than grade-A parts.

3. Grade-C (Matte finish)

Matte is a Grade-C finish option made by grit sanding stones, and it creates a non-glossy surface texture.

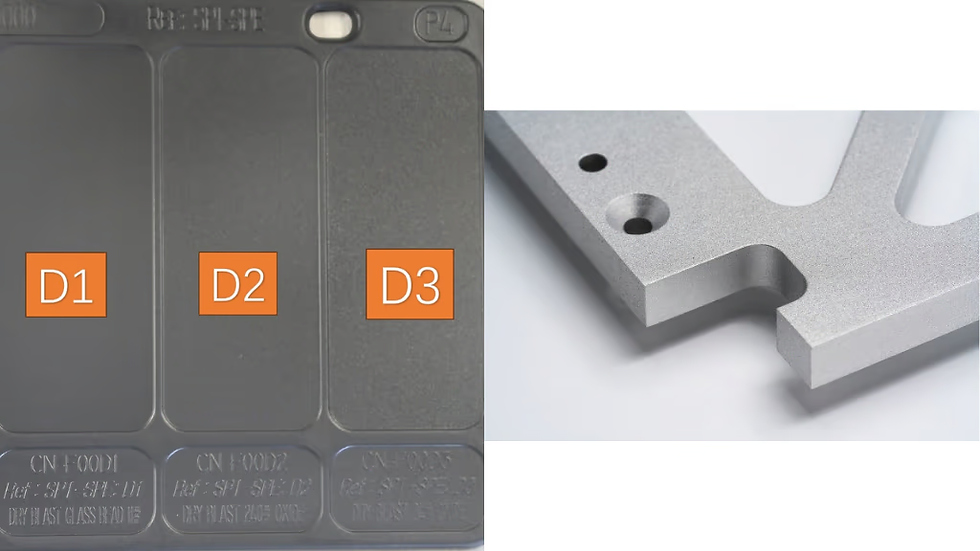

Grade -D(Texture finish)

Texture finish is a much rougher finish made by abrasive blasting with sand or glass beads

Conclusion

The injection molded part determines the kind of surface finish that has been chosen. To simplify, textured finishes give non-slip grips to handles, which means that they are perfect for daily use. Gloss finishes, on the other hand, add aesthetic value to those parts that need a high-standard, decorative appearance. The choice depends on the need for the product to be functional, aesthetic, or both.

Contact us today to discuss your project and receive a free quote.

Comments