SG Service Of Die Casting

- Jul 23, 2025

- 1 min read

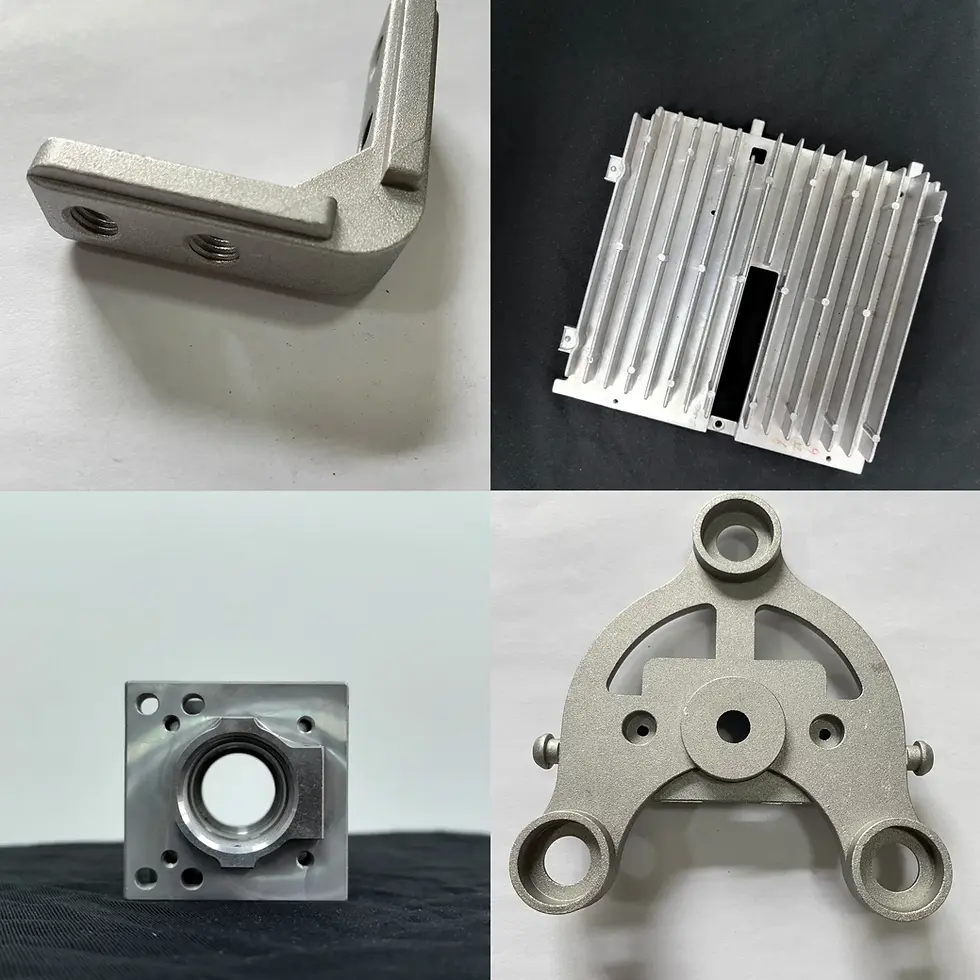

SG Prototype provides high-quality die castings with excellent dimensional accuracy and surface finish. Our service minimizes post-processing, enhances part compatibility, and accelerates production while reducing costs.

What is die casting

Die casting delivers unmatched advantages for volume production. By injecting molten aluminum or zinc alloys, etc., into steel molds under extreme pressure, and finally taking out the metal parts with complex shapes and precise dimensions.

Why choose die casting?

Die casting produces metal parts with complex structures, excellent strength, and fine surface quality in large quantities with high efficiency and high precision. It is also great for the automotive industry as well as aerospace, electric, kitchenware, and hardware applications. Materials commonly used for die casting in SG prototypes include Aluminum alloys, Zinc alloys, Magnesium alloys, and Copper alloys, among others.

Case study in SG

1. Heat Sinks with aluminum die casting

This aluminum die-casting heat sink was designed for a European client to help dissipate the heat generated by electronic components, thereby maintaining the device's normal operating temperature. The design of this heat sink features multiple fins to increase the heat dissipation area and enhance heat dissipation efficiency.

2. More cases for die casting parts

Seeking die casting solutions with fast delivery?

Request a feasibility analysis today.

Comments